Industrial Computer Buying Guide (Industrial Computers)

Industrial computers, as the name suggests, are computers used for industrial activities such as automation, manufacturing (production of goods), and autonomous robotics. Industrial PCs are often the first choice for industrial workloads, as they tend to be made from industrial-grade components that are more reliable and durable than their consumer-grade counterparts, and taken to the extreme in terms of mission-critical reliability. As a result, industrial computer hardware tends to be slightly more expensive than typical desktop computers. However, the total cost of ownership proves to be a major return on investment in terms of reliability and performance.

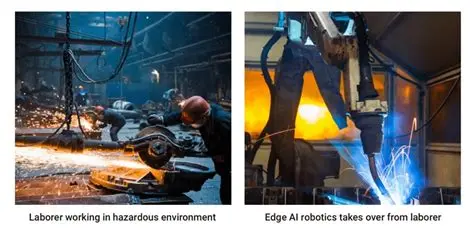

Industrial PCs are ideal for industrial workloads because they are designed to operate in harsh environments, so if you need to deploy your system in very cold or hot environments or subject to frequent shock and vibration, you should choose industrial PCs. computers designed and built to withstand harsh environments as needed.

While people may not need an industrial PC on their desktop at home, these powerful computing solutions are being deployed at IoT scale for enterprise applications and workloads.

A key characteristic of rugged industrial computers is that they are designed and manufactured to be reliable, stable and efficient no matter what environment they are in. They are especially useful for reducing downtime on consumer PCs with non-industrial workloads that users typically expect.

What are industrial computers used for?

Industrial computers are used in industrial environments to control processes, inspect products or components, and collect data. Industrial computers are equipped with I/O cards that can be plugged in to control various types of equipment in an industrial environment. In addition, serial, analog, and digital ports can be added to an industrial computer to suit your specific needs.

Industrial computer and desktop computer

Industrial computers differ from regular desktop computers in that they are used in very specific ways, depending on the tasks you want them to perform and the environment in which they are used. Although it seems that industrial computers are the same as regular computers because they have the same basic components such as processor, RAM, hard drive and graphics card, they are very different in terms of usage and operating environment.

This is because the parts they use are industrial grade,and systems are designed to withstand extended temperature ranges, higher input voltage peaks, power protection, ingress protection, shock and vibration. a few examples.

In addition, these custom-built computer systems are designed to withstand extreme shock and vibration that conventional PCs cannot withstand for extended periods of time. In addition, these computers comply with the stringent standards and guidelines for military electronic equipment.

For example, a popular specification for industrial computers is that they meet the MIL-SPEC-810G standard for shock and vibration: 50G shock and 5GRM vibration.

Industrial computers must be reliable, which means that they must provide optimal performance 24/7, as downtime in industrial environments often results in lost profits.

Some of the main differences between industrial and conventional computers will now be listed in more detail.

1. Build quality and reinforcement

The most noticeable difference between an industrial computer and a typical desktop computer is the build quality. Industrial computers are often used in environments where computer systems are exposed to extreme heat, cold, debris, dust, vibration, and shock. Therefore, ruggedized industrial computers are designed and manufactured to operate in such environments.

Wireless construction Materials similar to those used in computer cases; Motherboards are reinforced to withstand frequent shock and vibration. In addition, all cables are excluded from the system to ensure that the industrial computer can withstand frequent shock and vibration without any loosening of the cable. These specialized computer systems are built in such a way that they can withstand severe shocks and vibrations that regular PCs cannot withstand for extended periods of time. These computers comply with stringent standards and guidelines for military electronic equipment.

2. Industrial Grade Components

The second important difference between a conventional computer and an industrial computer is that an industrial computer is made up of industrial-grade components. Industrial grade components are more reliable than consumer grade parts because they are rigorously tested to ensure optimum performance even when used in harsh environments.

All products, from main PCB boards to soldering capacitors, are specially selected and integrated into the system to ensure that industrial computers can operate reliably in harsh environments that are unfavorable for computer systems.

In addition, another important advantage of usingThe use of industrial grade components is durability. For example, the Intel IoT Group Embedded Silicon Roadmap promises a 15-year support and availability lifecycle. This is a huge advantage for industrial applications requiring long life and a fixed specification for maximum reliability.

3. Protection against dust and debris

Industrial computers are designed to resist dust and debris. This is because industrial computers are often used in places such as factories, kiosks, machine tools, cabinets, vehicles, or mines where there is a lot of dust and debris that can damage computer systems.

As a result, many industrial computers do not have fans or vents in their chassis. The fanless design of industrial computers allows them to operate in an environment full of dust and debris because the system is completely isolated from the outside environment.

Removing the fan means that air does not need to circulate inside the system, allowing industrial computer manufacturers to design their systems without any openings. This allows fanless systems to operate in these environments without worrying about dust and debris getting into the system and damaging its internal components.

This is different from regular desktop computers, which use fans to circulate air around the system to cool it. Active cooling often damages computers by allowing dust and debris to enter the system, causing fans and other components to fail.

4. Ability to withstand extreme temperatures

Industrial computers are more versatile than personal computers because they can withstand a wider range of temperatures. For example, a typical desktop computer can operate at temperatures between 10°C and 50°C without problems.

However, fanless industrial computers can operate optimally in temperatures ranging from -40°C to 85°C. Industrial fanless computers can operate at such low temperatures because the closed system is passively cooled by heatsinks. The cooling fans inside the computer provide cooling by dissipating heat from inside the computer to the inside of the computer.

5. Ability to withstand shock and vibration

Another advantage of industrial computers over standard personal computers is that industrial computers are designed and built to withstand frequent and sustained shock and vibration. Systems that cannot withstand shock and vibration in such an environment will not be able to move continuously and are often subjected to shock and shock. This is because the motherboard may be bent or the connector may be loose. That's why we build industrial computers with heavy-duty mechanical construction and eliminate the use of cables, eliminating the possibility ofcables falling out of the connection. Today's rugged industrial computers withstand 5GRM vibration and 50g shock.

6. Scalability and durability

In terms of scalability and durability, industrial PCs are more scalable than desktop PCs and therefore last longer. Many industrial computer components can be used for 15 years, Longrui Zhike provides you with a long-term embedded computer solution that cannot be obtained with ordinary computers.

Leave a Reply