Scheme of designing a video surveillance system for a security company

In a modern enterprise, a CCTV system is being implemented at the factory, and the security department can carry out all-weather video surveillance in real time at the gates of the factory territory, factory buildings, office buildings, perimeter walls, warehouses, etc.

Scheme design

The project plan uses a video surveillance system consisting of a main workshop and an auxiliary workshop. The video surveillance image consists of front camera, encoder, network switch, monitoring platform software, server, control keyboard, monitor, decoder and disk array.

Using IP system architecture, the system is composed of external IP cameras, storage management servers, video management servers, decoders, video walls, etc. The system is composed of 1000M/100M Ethernet LAN, network cameras, regional network switches, backbone switches, monitoring Consists of central management platform, IP storage device and monitoring terminal. The communication network environment must be equipped with Category 6 network cable (less than 90m long) or optical fiber (more than 90m long). accept TCP/IP.

1. Composition of the system

Intelligent recognition and dynamic deployment management system in the factory is composed of: data simulation system, external data acquisition system, cluster comparison service system, transmission service system, background control system, alarm system, mobile phone alarm client, license plate recognition. early warning system, display system and other parts.

The main control center of the monitoring system is equipped with a video management server, centralized storage equipment, TV wall, control console, security cabinet, etc. to centrally manage, control and store all front cameras on the ground. and underground plant premises. Users can view, control, playback or download it in real time, realizing the networking, digitization and intelligence of the video surveillance system throughout the production area.

2. Regional monitoring design

According to the location and function of buildings, production monitoring can be divided into the following four areas:

1. Peripheral surveillance zone:

Mostly on the periphery of the building, video surveillance is usually installed along the wall and a perimeter protection system is installed. Once an external intrusion detector is detected, the alarm can be immediately sent to the intelligent control center so that it can be found and dealt with in time;

2. Conventional protected areas:

Including corridors, corridors, fire exits and other public areas, you can clearly understand the flow of personnel in the factory;

3. More important areas:

Including entrance and exit halls, elevators, warehouses, loading and unloading areasetc., mainly for accurate and convenient monitoring of people and vehicles arriving and leaving, to ensure the safety of goods and people;

4. Important areas:

Including key areas such as laboratories, R&D centers and financial offices. Due to the high value of development, cameras will be installed at the entrances, exits and aisles of laboratories and R&D centers to monitor daily dynamics from a wide range. laboratories and research centers It will be monitored by cross-located cameras.

3. System Architecture Diagram

4. Network structureThe main function of the network monitoring and transmission system is to access various monitoring resources, provide basic guarantees for various applications of the central management platform, and improve the service for various users. The network structure is shown in the figure below:

1. Core layerThe core layer is responsible for the video transmission core of the regional center and the power plant center. Its main function is to serve as the backbone of a high-speed interconnection network, realize optimized packet throughput between nodes, and optimize transmission performance. The main equipment at the core level is the core switch. As the center of the entire network, the configuration performance of the core switch is relatively high.

2. Access levelExternal access to video resourcesThe external network uses an independent IP address network segment to connect various external monitoring devices. External video resources are connected to the monitoring center or data room through an IP transmission network for aggregation. External network access usually uses the following methods: for long distance transmission, it is usually point-to-point fiber optic cable access and point-to-multipoint PON access. to-point or point-to-point For multipoint access, for short distance access, direct access to the switch can be used;

5. Network Bandwidth Requirements.Including the network transmission process and the overhead of other applications, the theoretical available bandwidth is about 80% of the bandwidth. quality video transmission, bandwidth used. A light load design is recommended, and the upper limit of the light load bandwidth is controlled within 50% of the channel bandwidth.

1. The network in which the base layer switch is connected to the switch uses optical modules for transmission, and the throughput must reach a gigabit or more. If the original bandwidth is not adequate, increase the bandwidth;</p >

2. It is recommended that the bandwidth between transmission equipment, such as fiber optic transceivers and access switches, reach 100M;

3. RekoIt is recommended that the bandwidth between transmission equipment, such as fiber optic transceivers, be up to 100M;

Depending on the actual needs of the project, network capacity planning can be adjusted accordingly.

6. Types of transmission methods

In a video surveillance system, the transmission of video signals is a very important part of the entire system. Although the cost of this part is small, it is related to the image quality and the effect of using the entire CCTV system. monitoring system, so you need to choose a reasonable transmission method. Currently, the most commonly used transmission media in high-definition video surveillance systems are twisted pair and optical fibers.

Seven, storage system

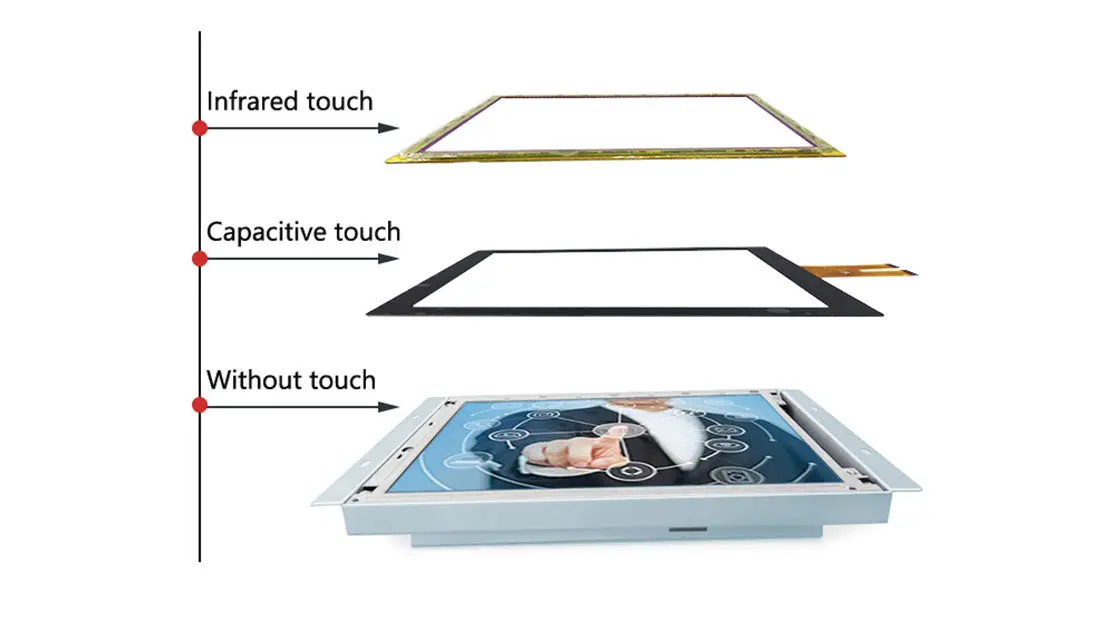

VIII. Decoding system

The decoder system is mainly to restore the external network video signal into a high-definition digital signal and output it to the display system for display. This decoding system has the functions of video decoding, splicing, control, etc. It integrates the original decoding equipment and splicing control equipment into an integrated device, and video decoding can be realized through the video management system management platform software. Output, switch control, large screen merging, and other functions that originally required multiple sets of software. Can support various output interfaces such as HDMI, DVI, VGA or BNC.

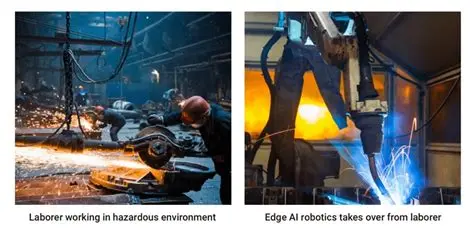

9. Additional options for scene monitoring:

See the following script requirements

Leave a Reply