How to choose an industrial computer?

Selection of the right industrial computer depends on the required computing performance, computer deployment environment, computer space, power source, and required connectivity.

1. Performance

The CPU is the heart of every industrial computer and is responsible for the overall performance of your chosen industrial computing solution. Therefore, it is essential to choose a processor capable of handling any task and workload.

In order to reduce the overall cost of industrial computers, people often want to reduce the CPU load. However, choosing a less powerful processor can result in slower performance, slower workflow, and downtime. Therefore, when choosing the right CPU for an industrial computer, you should choose a powerful option that ensures a stable and uninterrupted workflow.

Industrial PCs are available in a variety of CPU options, from quad-core Intel® Celeron® processors to 9th Gen Intel® Core® i7 processors. Intel processors are popular among industry professionals for their performance and reliability. When a small industrial PC is required to power devices such as IoT gateways or energy-saving kiosks, the Intel® Celeron® J1900 processor is sufficient for these applications. However, suppose you need to deploy an industrial PC for automated inspection and intelligent monitoring; having more cores on a single silicon chip will help better consolidate workloads. You'll benefit greatly by choosing an Intel® Core® i3, i5, or i7 processor, as such tasks require the enormous processing power that these processors provide. The Intel Core series processors have many features built directly into the chip that allow users to maximize performance, especially in enterprise deployments.

In addition, learning about the difference between SoC and Socket processor will help you choose the right processor option for your workload.

SOC (system on a chip) and socket computer

A system-on-a-chip (SoC) is an integrated circuit that integrates all the components of a computer on a single substrate. For example, in an SoC, the processor, RAM, and GPU are on the same chip. SoCs are typically low power and extremely compact, making them ideal for applications such as IoT gateways and edge computing.

On the other hand, socket processors tend to be more powerful and provide better performance than single-chip systems because they have more cores and can run at higher temperatures. However, SoCs still find their place in industrial workloads due to their high efficiency and optimal size, which provide more flexibility for industrial applications and deployments.IoT that require low power computing performance.

2. Environment

The choice of an industrial computer depends on the deployment environment of the computer. Some people prefer to use a regular desktop computer in an environment with extreme temperatures, shock, vibration, dust, and debris, and then wonder why the computer crashes so quickly. This environment requires an industrial computer to handle the unstable environment in which the system will be deployed.

Industrial embedded computers are designed and manufactured with reliability in mind, allowing them to be used in extreme high or low temperatures, vibration, shock, dust and debris.

Rugged industrial PCs can handle these kinds of workloads with a fanless, cableless, and rugged design. By eliminating fans and vents in industrial computer systems, industrial computer manufacturers have eliminated the possibility of dust and debris entering the system, which can cause internal components to fail. The result is an ultra-reliable industrial computing solution that minimizes downtime and enables reliable operations 24 hours a day, 7 days a week.

3. Application

The choice of a suitable industrial computer depends on the purpose for which you need an industrial computer. For example, industrial computers are often used in industrial environments as workstations and human-machine interfaces in manufacturing plants, food processing plants, farms, warehouses, transportation hubs, medical facilities, hazardous areas, and various other places.

The choice of industrial computer will depend on the intensity and number of applications you want the system to run. The larger the application and the more demanding the software, the more processing power you will need to keep your system running smoothly and reliably.

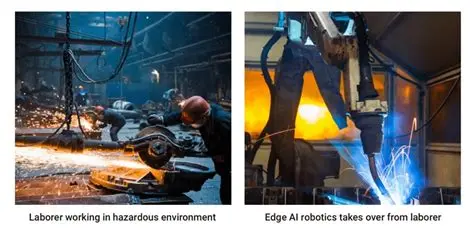

With the rapid development of the Internet of Things, rough industrial computing is becoming increasingly important. This is due to the fact that some applications require data processing and analysis at the edge of the network, where industrial computers come to the rescue. Since data does not have to be transmitted over long distances, peripheral computers can perform real-time data processing, analysis, and decision making, supporting many applications that require such processing and analysis.

4. Communication

After you've figured out the processing power you need, the environment your industrial PC will run in, and the applications you'll be running, it's time to think about configuring your system's connection settings.

Having a securely connected industrial computing solution is critical to connecting your system to a variety of sensors, inputs, networks and accessories,which you may have. The industrial computer can be configured with the following connectivity options: Bluetooth, Wi-Fi 6, 4G, 5G and 10GbE LAN ports.

In addition, the industrial computer is equipped with a USB 3.1 Gen 2 port, allowing your system to connect IoT smart sensors and transfer data at 10 Gbps. Also, if you have legacy technology, your industrial computing solution can be configured with the serial ports that are still in use today due to their reliability and flexibility.

The I/O expansion capability with modular daughter boards increases the flexibility of our industrial computing systems by adding a variety of additional ports, including RJ45/M12 LAN, serial ports, USB ports, DP ports, and DIO ports. .

Bluetooth is typically used to connect industrial computing equipment to one or more sensors and/or devices. 4G and 5G are used to connect devices to the Internet when it is not possible to connect to the Internet through a wired connection or Wi-Fi. No matter what connectivity options you need, the system can be customized to suit your specific needs.

5, storage, memory and expansion

The last thing you should consider when choosing an Industrial PC is the storage solution you need for your workload. Industrial computers can be equipped with standard hard drives (hdd) and solid state drives (ssd). If there is a need to run common applications that do not require real-time access, the system can be configured with mechanical drives.

However, if high-speed access to localized storage is required, the system must be equipped with an SSD. Solid State Drives provide extremely high data transfer rates, allowing you to process data and make real-time decisions. In addition, equipping the system with an SSD can make the system more reliable and more resistant to frequent shock and vibration than a hard drive, since the SSD does not have moving platters that can be damaged.

Also, if you need the latest high-speed storage, you can customize your system with the M.2nvme storage solution. NVMe drives connect directly to the PCIe protocol for incredibly fast transfer speeds. The NVMe drive has write speeds up to 2500MB/s and read speeds up to 3500MB/s. However, conventional SSDs and HDDs still have their place as they offer the massive storage capacity that some businesses and organizations require in their storage infrastructure.

You should also consider how much RAM you want to equip your industrial PC with. RAM has a big impact on the manufacturerness of the system. The more RAM you have, the smoother your system's performance will be because it can cache data faster closer to the CPU architecture. RAM is an extremely fast short-term storage device that allows your processor to access the data and applications you use. The more memory you have, the more applications and data you can download so they can be accessed faster, speeding up your industrial computing solutions.

Leave a Reply